[Project Report] Hunan Dingli Technology Co., Ltd. has adopted LiDAR Electric's low-voltage filter compensation products for its decomposing crack furnace equipment.

Time:

2021-06-24

Hunan Dingli Technology Co., Ltd. offers products that cover various fields including hard alloys, battery materials, new energy, C and SiC ceramic fibers, and vacuum heat treatment. Based on fully digesting and absorbing advanced technologies from both domestic and international sources, we have created products that feature the "Dingli" characteristics and meet market demands.

Hunan Dingli Technology Co., Ltd. products cover multiple fields including hard alloys, battery materials, new energy, C and SiC ceramic fibers, vacuum heat treatment, etc. Based on fully digesting and absorbing advanced technologies from both domestic and international sources, we have created products with "Dingli" characteristics that meet market demands. In pursuit of higher technology and continuous innovation of products to meet customer needs, through our continuous efforts, "Dingli Technology" has developed a series of specialized equipment for powder metallurgy, lithium-ion battery material production equipment, C and SiC ceramic fiber material equipment, solar polycrystalline silicon casting furnaces, vacuum heat treatment equipment, etc., and has the capability to design and customize special equipment according to user needs.

Hunan Dingli Technology Co., Ltd. is a partner in China's aerospace engineering, assisting the "Fendouhao" in exploring the Mariana Trench.

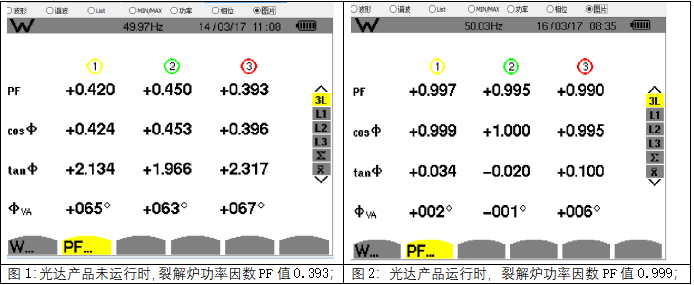

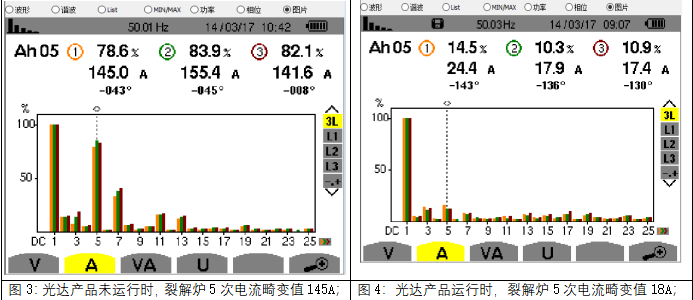

When the large cracking furnace equipment of Hunan Dingli Technology Co., Ltd. is in operation, the reactive power demand is large and rapid, and it generates 5th and 7th harmonic impacts on the precision of the equipment.

This project uses the low-voltage intelligent filtering compensation device TSVGGD from Guangda Electric, which is used for reactive power compensation and harmonic treatment in power systems, featuring low investment, small active power loss, convenient maintenance and operation, energy saving and consumption reduction.

After the project was delivered and put into operation, the power factor has always been maintained above 0.95, the total harmonic distortion of voltage is 1.8%, and the total harmonic distortion of 5th current has been reduced from 145A to 18A, effectively saving electricity costs while improving power quality. The success of this case demonstrates Guangda Electric's professional strength in the field of reactive power compensation.

Guangda Electric, as a high-tech enterprise integrating R&D, production, sales, and service, is committed to providing customers with first-class power quality solutions. We welcome customers to discuss cooperation!

Related Cases

Follow Us

Guangdong Guangda Electric Co. Ltd.

Tel:18028173868

E-mail:gdgddq@126.com

Web:www.gd96.com

Add :Building 3, No. 613, Xingtan Shuixiang Avenue, Gaozan Village, Xingtan Town, Shunde District, Foshan City, Guangdong Province