The manufacturing process of ceramic ball mills has high power consumption and suffers from serious power factor deficiency. How can this be resolved?

Time:

2019-10-07

The transformer supplies power to 12 ball mills, each with a power rating of 250 kW. The power factor is severely inadequate, causing significant pollution to the power grid and poor quality of electrical energy. This poses safety risks for equipment operation, leads to serious heating losses in cables, causes failures in electrical equipment, and results in tripping.

Customer Name:Qingyuan Shunchang Ceramics Co., Ltd.

Harmonic Load:Ball Mill

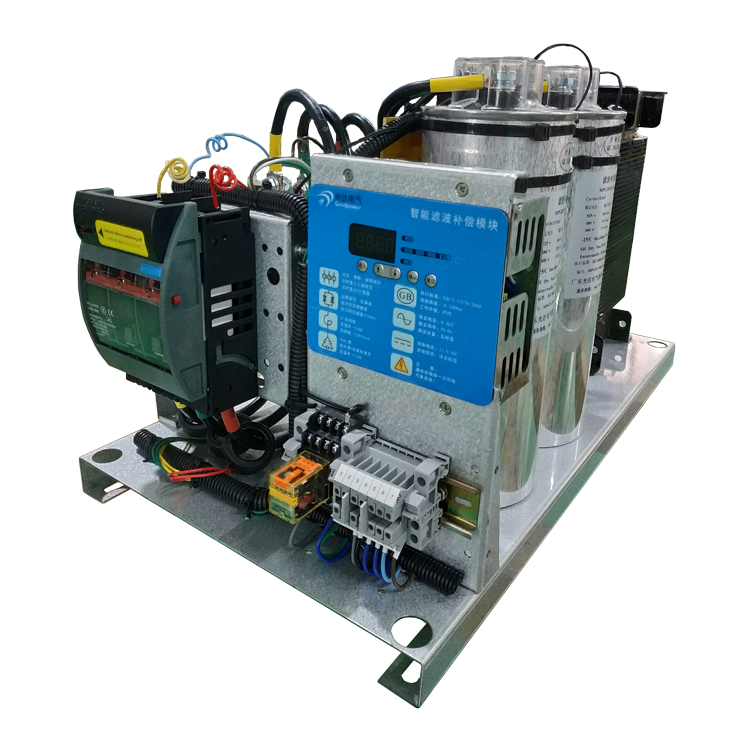

Purchased Equipment:Intelligent filtering compensation module for the ceramic industry

Project Background

Qingyuan Shunchang Ceramics is a large modern building ceramics enterprise integrating R&D, production, marketing, and service. Currently, it has 6 building ceramics production enterprises and more than 10 finished product production lines, with a rich variety of products covering multiple brands such as micro powder bricks, glazed tiles, microcrystalline stones, porcelain tiles, and antique bricks. It has several independent brands including "Shangyun", "Fuerjia", "Zhuoguan", "Suofuna", and "Pinrui", with a marketing network covering many regions both domestically and internationally.

Electricity Overview (Ball Mill)

According to the on-site investigation of Qingyuan Shunchang Ceramics Co., Ltd., the customer has 4 transformers with a rated capacity of 2500kVA and a voltage level of 10kV/0.4kV, of which 3 transformers are running in parallel; the main load: each transformer supplies 12 ball mills, with each ball mill having a power of 250kW;The power factor is severely insufficient, causing serious pollution to the power grid and the quality of electrical energy, posing safety hazards for equipment operation, with severe heating losses in cables, leading to equipment failures and tripping.

Design Plan

For the low-voltage side of each transformer, we design to retrofit with our company'sIntelligent filtering compensation module for the ceramic industryZBMGD,to improve the power factor, reduce current, lower reactive power, reduce cable heating, decrease cable losses, enhance power supply safety, expand power supply capacity, and achieve comprehensive energy efficiency management.Through comprehensive management of power quality, effectively protect important precision instruments, equipment, and computer systems, thereby extending the service life of the equipment and reducing maintenance costs.

Effect Analysis of Intelligent Filtering Compensation Module for the Ceramic Industry

Intelligent filtering compensation module for the ceramic industryAfter the device is put into operation, the original ordinary compensation cabinet of the distribution transformer, after upgrading and transformation, effectively improves the power quality on the low-voltage bus side, achieving the following goals:

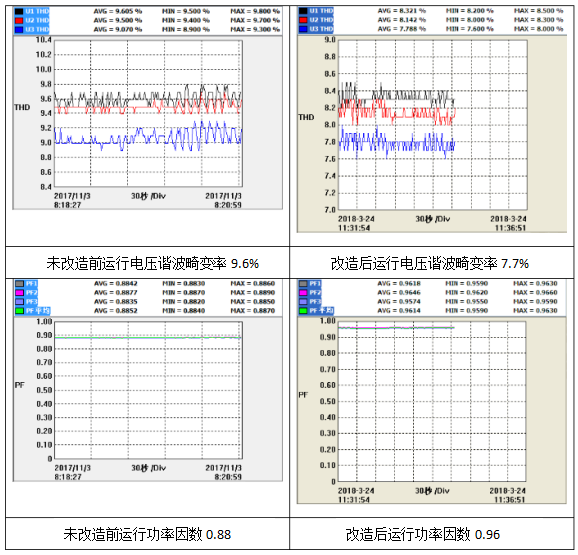

1. After matching the original compensation cabinet with the 4 transformers of 2500kVA and upgrading it,the average monthly power factor of the distribution room is not less than 0.95;

2. Except for the background voltage harmonics, the voltage distortion content of harmonicsmeets the national standard limit within 5%,,the harmonic current distortion rate is reduced to within 15%;the total distortion rate of voltage harmonics and the total distortion rate of current harmonics of each transformer have significantly decreased, improving the on-site power quality.

One of the electrical rooms compared operational data.

Improving energy efficiency and power quality is what Guangda has always been committed to providing as an optimization solution for power systems. We have a professional team that can provide customized solutions based on the specific needs of customers, bringing more stable and high-quality power support to customers' production and operations. If you have related issues, feel free to contact us at any time.

Related Cases

Follow Us

Guangdong Guangda Electric Co. Ltd.

Tel:18028173868

E-mail:gdgddq@126.com

Web:www.gd96.com

Add :Building 3, No. 613, Xingtan Shuixiang Avenue, Gaozan Village, Xingtan Town, Shunde District, Foshan City, Guangdong Province